Batch Process Control

A consumer goods processing plant required a system that would add a specific amount of water to a chemical blending operation every time it was started.

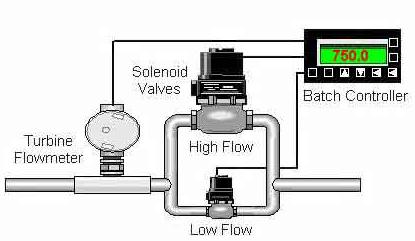

A turbine style water meter with an electronic pulse output was installed upstream of two solenoid valves as shown above. The pulse signal from the flowmeter was sent to a batch controller. Two sizes of valves were used to control the water flow, one was 1 inch, the same size as the pipe diameter and one was 3/8 inch, approximately 30% of the pipe diameter.

The total amount of water required for a batch is programmed into the controller. When the start button on the controller is pushed, both solenoid valves open and the flow rate and total are displayed. The volume of liquid is counted and totaled by the controller. At a specified preset amount, usually 95% of the total liquid required, the controller closes the larger solenoid valve leaving the smaller solenoid valve open.

The smaller solenoid valve reduces the flow of water in the operation to insure a more precise shutoff at the exact amount of water required by the batch process. In addition, the smaller solenoid valve helps avoid water hammer in the piping when the valve closes to shut off the flow.

With the wide range of materials available for valves and flowmeters, other liquids can be controlled with this system as well.

- Pre:Commercial Laundry Wastewater 2016/5/24

- Next:Teledyne LeCroy, Coherent Solu 2016/5/11